The Role of Molecular Sieve Manufacturers in Advancing Chemical Separation Technologies

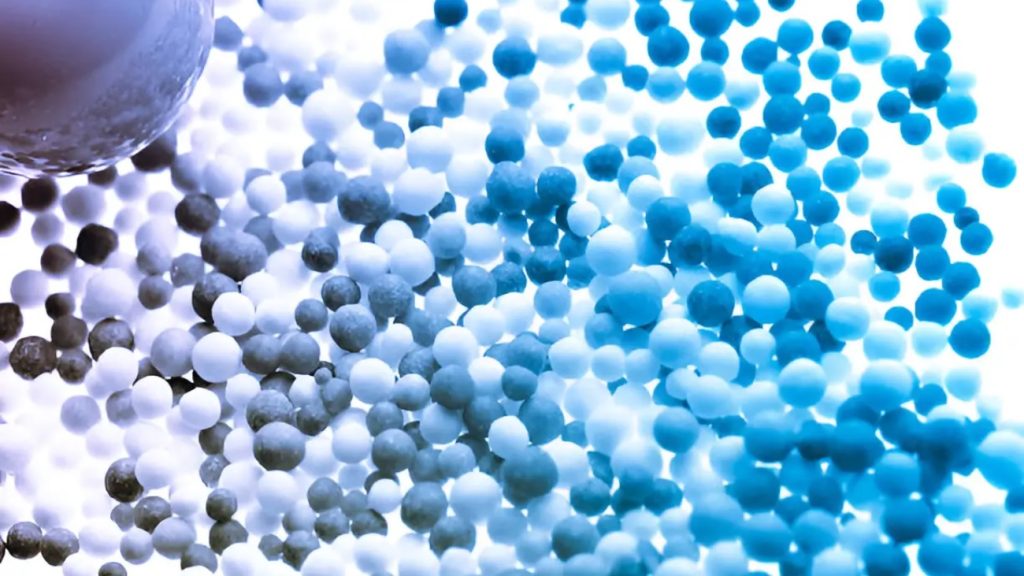

Molecular sieve manufacturers play a crucial role in the advancement of chemical separation technologies. Molecular sieves are a type of porous material that separates molecules based on their size and shape, making them indispensable in a variety of chemical and industrial processes. The continuous innovation and development by these manufacturers are essential for improving efficiency, selectivity, and sustainability in chemical separations. Molecular sieves are crystalline materials with uniform pore sizes that allow them to selectively adsorb molecules of certain sizes while excluding others. This unique property makes them ideal for applications such as gas separation, dehydration, and catalysis. The most common types of molecular sieves are zeolites, silica gels, and alumina.

Enhanced Selectivity and Efficiency – Jalon molecular sieve manufacturers are constantly developing new materials with improved selectivity and efficiency. For example, the creation of novel zeolite frameworks with specific pore sizes allows for more precise separation of molecules. These advancements enhance the performance of separation processes, leading to higher purity products and reduced operational costs.

Development of New Materials – Manufacturers are exploring new types of molecular sieves, such as hybrid organic-inorganic materials and metal-organic frameworks MOFs. These materials offer unique properties, such as higher surface areas and tunable pore sizes, which can be tailored for specific applications. For instance, MOFs have shown promise in capturing greenhouse gases and separating complex mixtures, contributing to environmental sustainability.

Scalability and Cost-Effectiveness – The scalability of molecular sieve production is a significant focus for manufacturers. Advances in synthesis techniques and the development of more cost-effective production methods help to reduce the overall cost of molecular sieves. This makes advanced separation technologies more accessible to a broader range of industries and applications.

Durability and Stability – Chemical separations often involve harsh conditions, such as high temperatures and aggressive solvents. Manufacturers are working on enhancing the durability and stability of molecular sieves to ensure they can withstand these conditions without degrading. Improved stability leads to longer service life and reduced maintenance, which is crucial for industrial processes.

Petrochemical Industry – In the petrochemical industry, molecular sieves are used for the separation of hydrocarbons and the removal of impurities. For example, they are essential in the production of high-purity ethylene and other olefins. Advances in molecular sieve technology enable more efficient separation processes, contributing to cost savings and improved product quality.

Pharmaceutical Industry – In the pharmaceutical industry, molecular sieves are used for the separation and purification of active pharmaceutical ingredients APIs. Enhanced molecular sieve materials can lead to more efficient purification processes, resulting in higher yields and reduced production costs.

The molecular sieve manufacturers are at the forefront of advancing chemical separation technologies. Their ongoing research and development efforts lead to the creation of more efficient, selective, and cost-effective materials. These advancements have a significant impact on various industries, from petrochemicals and pharmaceuticals to environmental applications. As technology continues to evolve, the role of molecular sieve manufacturers will remain critical in driving innovation and improving the effectiveness of chemical separation processes.